The Future of Packaging: Advancements in Overwrapping Solutions

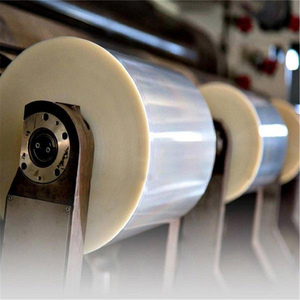

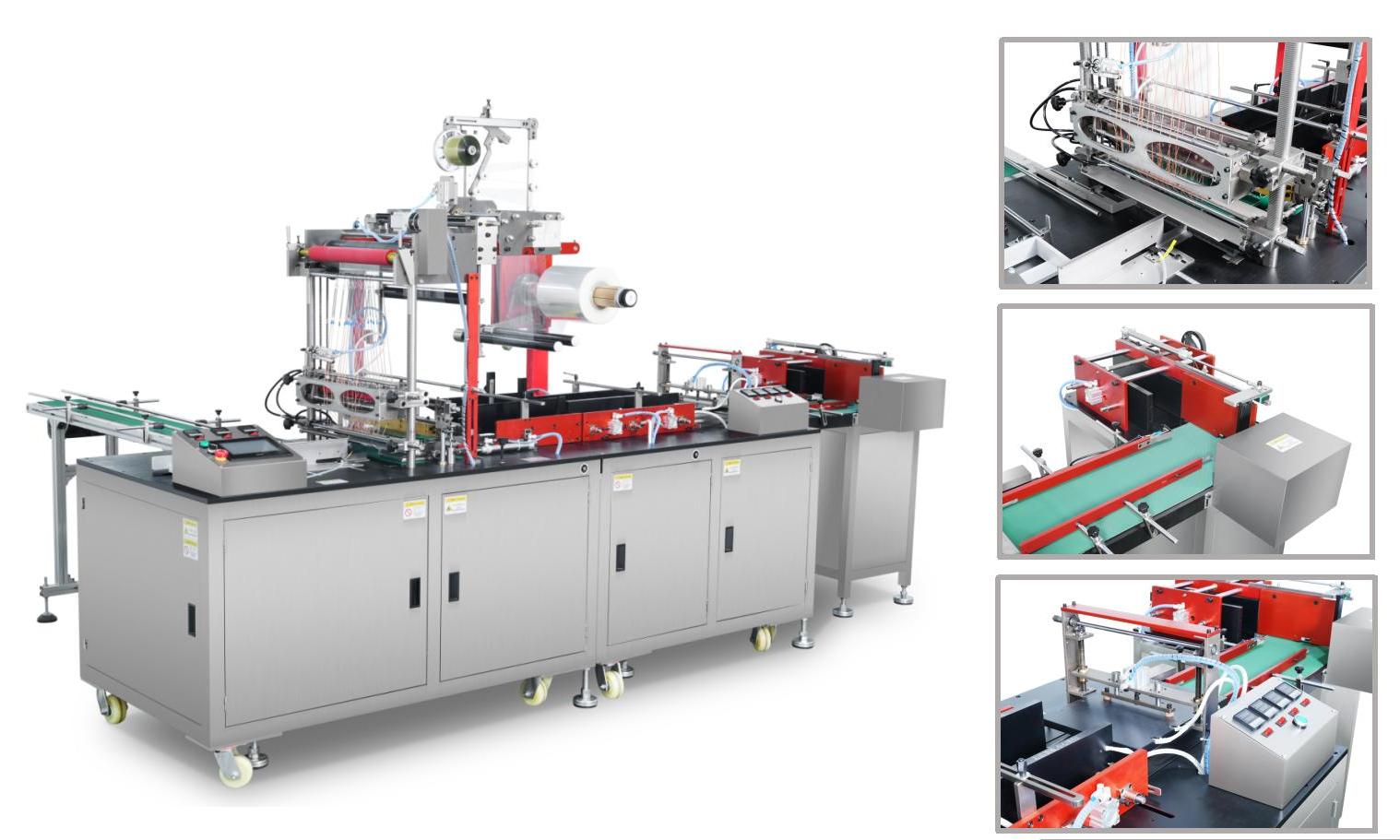

Recent advances in fully automatic cellophane film wrapping machines have introduced precision digital controls, modular quick-change tooling, and integrated tear-tape applicators, collectively driving higher throughput, reduced downtime, and consistent wrap quality across tobacco, pharmaceutical, food, healthcare, cosmetics, and audiovisual packaging lines. The adoption of stainless-steel GMP-compliant frames, stepless speed regulation via digital frequency converters, and comprehensive safety interlocks has enhanced operational reliability and hygiene standards. Moreover, built-in film-feeding clutches for trial runs minimize material waste during setup, contributing to cost-effective production.

️Innovations in Machine Design

1. Precision Digital Control

-

Stepless speed adjustment through multifunctional digital frequency converters allows seamless matching of wrapping speed to production requirements without mechanical adjustments.

-

PLC-based interfaces and, in some models, touchscreen HMIs enable intuitive operation and remote diagnostics, reducing operator training time and maintenance effort.

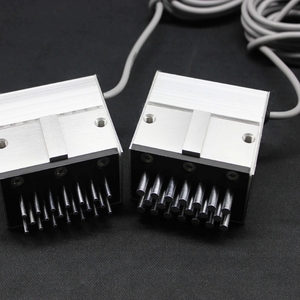

2. Modular Quick-Change Tooling

-

Modular mold assemblies provide rapid swap-out capabilities, cutting format-change downtime to under 20 minutes in advanced configurations.

-

Standardized jigs and adjustable guides accommodate a wide range of box dimensions (e.g., 30–160 mm length, 10–35 mm height) without extensive realignment.

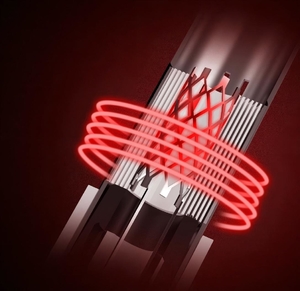

3. Integrated Tear-Tape Applicators

-

Built-in tear-tape devices automatically apply pre-adhesive easy-open strips (gold or transparent), enhancing consumer convenience and reinforcing anti-counterfeiting measures.

-

Tear-tape placement accuracy is maintained through synchronized servo drives and photoelectric film-tracking sensors.

4. Safety & Waste-Reduction Features

-

Multiple interlocks and fault-alarm systems halt operations instantly upon jam detection or safety-door opening, ensuring operator safety.

-

A film-feeding clutch enables trial runs without consuming full rolls, avoiding unnecessary waste during setup and testing.

Industry-Wide Applications

Fully automatic cellophane overwrappers serve a diverse product portfolio:

-

Tobacco & Confectionery: Cigarette packs, chewing gum, sugar cubes

-

Pharmaceuticals & Supplements: Health-care capsules, transparent soap boxes

-

Personal & Home Care: Condoms, mosquito coils, erasers, e-cigarettes

-

Media & Electronics: Cassette tapes, VCDs/CDs, DVDs, floppy disks, square batteries

-

Stationery & Specialty Goods: Playing cards, printer cartridges, small gift boxes

The combination of clear overwraps and tear-tape enhances brand visibility on shelves while providing anti-counterfeiting, moisture-proof, and dust-proof protection.

Industry-Leading Suppliers

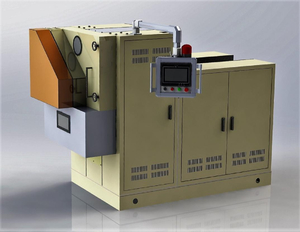

UPPERBOND Overwrapping Equipment

UPPERBOND's high-speed transparent film wrapping machines feature servo-driven film tension control, 120 packs/min capacity, and touchscreen PLC interfaces for seamless line integration and remote troubleshooting.

BINHAO BOPP/PVC Films & Tear Tapes

BINHAO supplies premium transparent films with low haze (<2%), good seal strength, and excellent barrier properties, suitable for food and non-food applications. Its self-adhesive tear tapes come in multiple widths, colors, and anti-counterfeiting designs to match brand requirements.

Conclusion

Objective assessments confirm that modern fully automatic cellophane film wrapping machines, augmented by UPPERBOND's precision overwrappers and BINHAO's high-clarity films and tear tapes, provide industries with end-to-end packaging solutions that elevate product presentation, safeguard against tampering and environmental factors, and streamline production through advanced automation and safety features.